Nowadays, in the production of individual spare parts for dentures and implants, they are increasingly using modern 3D-modeling technologies, or CAD / CAM. In contrast to the traditional, mechanical method of production, the usage of computer programs and high-precision electronic printers, milling machines allows us to rethink the processes of autonomy and automation of dental laboratories in a new way.

Also, these tools allow you to achieve maximum accuracy of the produced models and significantly reduce the time cost of production. In this review, we will examine in more detail the most popular software that today should be in the arsenal of a modern dental laboratory.

Table of Contents

What is CAD / CAM, CAD

- tabs

- all-ceramic bridges;

- ceramic crowns processed by a milling cutter;

- veneers;

- abutments (implants).

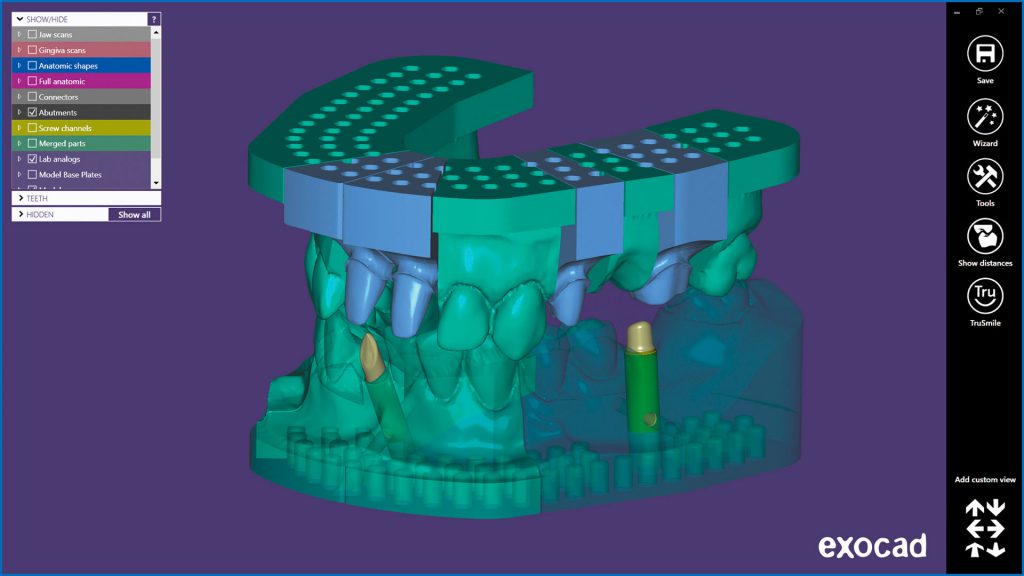

1. Exocad

This software has many advantages, that explains its popularity among specialists:

The ability to create virtual models using the maximum number of necessary parameters: Bennett`s angle, condyle angle, articular path, immediate lateral displacement, magnitude of retrusion and protrusion, etc.

The ability to integrate with various devices from other manufacturers;

simple and understandable interface – suitable for both beginners and represents a powerful tool in the hands of specialists.

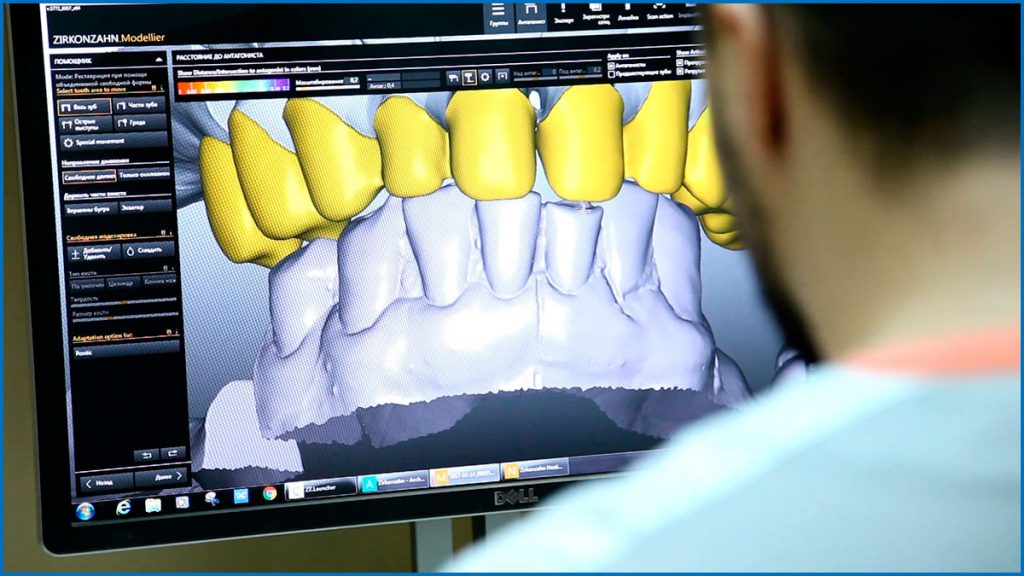

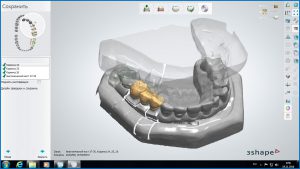

2. Shape 3D

3Shape RealView ™ – an application that allows dentists to create images, adding to the project photographs of the patient’s face, developed 3D-models. This tool allows you to conduct a modern analysis of the work done, as well as to achieve maximum results in optimal aesthetic characteristics.

Dental System ™ is a 3D modeling engine that provides a powerful automated workflow, including large order management and fast interaction.

3Shape Dental Desktop ™ is a platform designed to unite all digital dental applications into an integrated interface, integrated into a common workflow – it does not matter if you work from a computer, tablet or phone. With another application, 3Shape Communicate® you can easily share scans and models in a shared cloud, and collaborate on projects with other doctors — dentists, surgeons, and dental technicians.

3. Avantis 3D

Virtual patient – combining in a single scene the data of the patient’s face (by photo or scan), dentitions and digital tomography data.

Diagnosis and detailed analysis of articulator, tomography data, analysis of TRG / TMJ, etc.

Ortho-design – planning the alignment of dentitions using visualization, analysis of approximate and occlusal contacts, designing models for the production of eliners, etc.

Implant master – position planning and designing templates, with various types of fixation and arbitrary parameters of the navigation system and guide bushings.

Gnato Studio – 3D analysis of the relative position of the elements used, calculation of the movement of the low frequencies and new joint data. The possibility of clinical 3D modeling.

4. ZWSOFT

- ZWCAD – a program for computer aided design 2D / 3D;

- ZW3D is a universal CAD / CAM solution.

- PC multiprocessor support;

- usage half of the RAM;

- the highest level of compatibility with DWG formats;

- Increased productivity, instant file opening speed and stability with large projects;

- Powerful functional API system.

- In a word, a very simple and affordable program, unpretentious in requirements.

5. Excel-Dental

There are examples when more accurate and better programs for analysis and teeth modeling are created on the basis of existing laboratory equipment.

The Italian company Excel-Dental is such example, because it is engaged in the production of professional dental equipment, including integrated CAD / CAM systems. The software here works in conjunction with high-precision modern equipment capable of performing any tasks and operations.

Capabilities:

1) At the initial stage, the casts are scanned and the model is created. In addition to traditional casts, electronic data from the patient’s oral scan in STL format can also be processed.

1) At the initial stage, the casts are scanned and the model is created. In addition to traditional casts, electronic data from the patient’s oral scan in STL format can also be processed.

2) Full contour restoration is possible without a model, in the case of working with titanium abutments or glass ceramics.

3) The ability to work with lithium-glass ceramic in software such as e.max CAD, Vita Suprinity and Mark II.

QStoma

And finally, I would like to talk about the unusual application service QStoma. This is not a special program integrated into laboratory equipment, or a frame for creating projects. QStoma is a specialized web software for dentists, orthopedists, orthodontists, and dental technicians. A convenient system for recording patient profiles and managing a clinic or dental laboratory. Although this service was created rather for summarizing routine data and for closer communication between the patient and the client, the doctor and the technician.

Nevertheless, here you can perform various specific operations of the treatment process:

The therapist can mark the surface of the teeth where the manipulations were performed on the dental formula.

Podiatrist, surgeon, implantologist depict the selected design and describe the indications for the dental laboratory in a suitable graphic editor.

The orthodontist will be able to depict and describe the chosen design, as well as save all the calculations in such programs as BJork, Larry White and McLaughlin.

A dental technician, in a graphical editor that is already convenient for him, can depict the design chosen by the dentist, describe the order and fill out the act of the completed project for the dentist.

CAD / CAM, this abbreviation from English literally means the following: Computer-Aided Design / Computer-Aided Manufacture.

For the first time, such systems appeared in 1980s, and were initially used in a slightly different field, and more specifically in the industry for the production of metal cutting machines and high-precision machining of parts in automobile manufacturing, jewelry processing and some other areas. Further implementation in various fields allowed the use of this technique in the dental field.

Nowadays, software and related equipment help at all stages of production – from design development to production of parts. Innovative electronic technologies are universally implemented in the methods of modern medicine and treatment.

In dental technology, CAD systems are used by leading laboratories and produce the following parts:

The CAD / CAM program recreates a three-dimensional anatomical shape for further press blanking. Subsequently, it is applied to the frame, and temporary crowns are projected into the full profile and other details are displayed.

The developing model is viewed at any desired angle, and the projection is viewed in a certain selected lighting. In addition, you can review and change any part of the object, up to a complete reconstruction of the structure. After clarification and approval of the project, a detailed project with drawings and numerical designations of dimensions is set on the apparatus for further production.

The developing model is viewed at any desired angle, and the projection is viewed in a certain selected lighting. In addition, you can review and change any part of the object, up to a complete reconstruction of the structure. After clarification and approval of the project, a detailed project with drawings and numerical designations of dimensions is set on the apparatus for further production.

The computerization of dental production provides virtually unlimited possibilities for restoration. Models made with using new technologies are characterized by ideal fit properties, enhanced biocompatibility, durability and a natural aesthetic appearance.

Various softwares

Today, there are many developed CAD / CAM softwares that perform various specialized tasks and differ in an individual interface and functionality. We will get to know more closely the leading software developments in this direction, which have rightfully earned recognition among hundreds of specialists and laboratories around the world.

Exocad positions itself as a manufacturer of a reliable, simple and stable platform suitable for most modern applications.

Actually, in laboratory practice, everything works as simple as possible. Individual moulds of the jaws are initially placed inside the apparatus and scanned in various positions, considered in relation to the frames of the articulator.

Similarly, the software scans the position of the virtual teeth relative to the hinge axis in space. In a custom application project, the model is located in virtual space. As a result, you can achieve excellent simulation results that are fully consistent with the individual characteristics of the patient’s jaw.

3Shape is another equally popular development company that creates 3D scanning solutions and software for CAD systems. Today, the company has 700 employees, including more than 275 product development specialists worldwide. Real innovation and the ability to imagine how medicine will look like in the future – this is what gives you the work with Shape 3D software modules. Also, developers implement into the functionality unique technologies of the “real future”.

Let`s get known about only a few of them:

Avantis 3D is a company that also develops digital CAD / CAM systems and offers more reasonable prices in comparison with similar foreign products.

This software also combines a number of modern and relevant technologies useful during sample creation:

ZWSOFT company has been known in the field of 3D modeling for more than 20 years (established in 1998), has headquarters in Guangzhou (China), and is one of the world’s largest suppliers of digital CAD / CAM software for digital design. Currently, the company has more than 180,000 customers from 80 countries (metal processing, architecture, jewelry, dental technology).

ZWSOFT company has been known in the field of 3D modeling for more than 20 years (established in 1998), has headquarters in Guangzhou (China), and is one of the world’s largest suppliers of digital CAD / CAM software for digital design. Currently, the company has more than 180,000 customers from 80 countries (metal processing, architecture, jewelry, dental technology).

The main software products created by ZWSOFT are:

Among the main functions that a modern modeling engine should have, ZWSOFT products are distinguished by interesting optimization solutions that provide the following functions:

For example, the S600 ARTI scanner – represents optical equipment working with a special program that is capable of reproducing images with an error of up to ≤ 10 μm. Another example is the M1 milling machine – 5 + 1 axes – capable of turning parts of any complexity, extreme precision and from any material: zirconium dioxide, titanium, glass ceramics, cobalt-chromium and others.

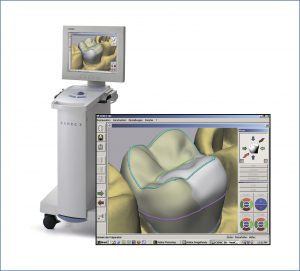

SolidWorks is a popular application, originally developed not entirely for dental purposes, although today it has been universally adopted by many dental laboratories for the filigree production of unique parts. According to the official website, “SOLIDWORKS CAM software” – powered by the CAMWorks engine – it uses unique algorithmic technologies that combine the modeling and production of three-dimensional models into one process.”

In this regard, I would like to separately mention the DELMIA Prismatic Machinist application, which sets the exact parameters for axial turning (milling) of parts, with test measurements and taking into account the exact future position of the model in space. A truly useful software product for learning the basics of 3D modeling in a well-transmitted virtual space. At a minimum, SolidWorks is useful for overall self-development!