Many patients explain their refusal to carry out restoration through prosthetics by the need to wear “non-native crowns” in the mouth for a certain time, to endure the painful procedure of grinding tooth enamel. Today, physical discomfort can be minimized with the help of modern dental restoration techniques, one of which will be discussed in this article.

Table of Contents

GENERAL PRESENTATION

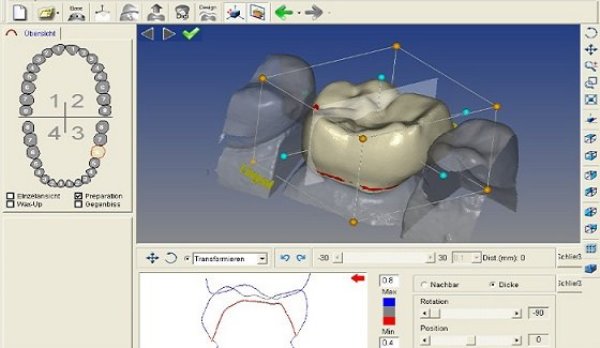

CAD CAM is a unique modern technology for the production of dental prosthetic products using panoramic 3D computer modeling and further manufacturing of the prosthesis on milling electronic equipment. The method is fundamentally different from standard production technologies with a manual method of higher accuracy of finished products, production speed and ease of operation.

The procedure includes the following stages:

- computer diagnostics;

- panoramic modeling of the system;

- production of the prosthesis;

- installation of the structure.

The main purpose of CAD CAM is the processing of high-strength materials and the manufacture of high-quality prosthetic structures that do not cause discomfort and have high aesthetic characteristics.

ADVANTAGES OF THE TECHNOLOGY

The technology has the following pronounced advantages in comparison with other methods of manufacturing prostheses:

- the ideal and most accurate fit of the product;

- durability;

- aesthetics;

- protection of hard tooth tissues, dentin from negative external influences;

- milling is carried out in such a way that does not affect the physical characteristics of the materials used;

- allows processing superhard materials, for example, zirconium dioxide, which is extremely difficult to give the desired dimensions and shape by manual production method.

THE CAPABILITIES AND TYPES

of the Cad Cam system open up wide opportunities for the manufacture of the following prosthetic structures and orthodontic devices:

- bridge-shaped devices and crowns of any length;

- crowns having a telescopic principle of structure;

- abutments for use in the process of prosthetics using the dental implantation method;

- veneers, inlays and other plates that protect and strengthen the tooth tissue;

- a pharmacological type of crowns.

There are two types of CAD CAM in dentistry:

- open devices are compatible and work perfectly with any consumables of most manufacturers of medical products;

- closed devices can be used only when working with a single consumable, which is usually produced by one company.

STAGES OF PROSTHETICS

The algorithm of actions of a specialist during prosthetics using CAD CAM systems is as follows:

preliminary preparation – one or a fragment of a dental unit is removed from stony deposits, professional cleaning and drying are carried out, after which the working area and bite are scanned with a special optical volumetric camera. This is how a computer 3D panoramic version turns out. In the same way, standard casts are scanned; the resulting image is processed by a special computer program that independently selects the optimal form of the planned restoration, taking into account the anatomical structure and physical condition of neighboring organs. At the same time, the doctor can make adjustments and corrections with the mouse. How much time it will take depends on the clinical situation and the complexity of the course of pathological processes. On average, this period lasts from 5 minutes to half an hour; upon completion of the modeling procedure, the document with the finished design is copied, and the information enters the system unit of the milling machine, which has an electronic operation programming system. From a fragment of a solid material, the specialist will produce an analog version that exactly copies the electronic panoramic model. The entire process takes no more than 10 minutes. To give the design higher aesthetic characteristics, a thin ceramic layer is worn on it, providing light reflection and translucency of the product; if zirconium oxides are used as the base component, the finished model must be maintained in a high – temperature furnace-this is necessary for sintering the material. After such processing, the device will acquire the necessary dimensions, hardness, become stronger and form the final color shade; after firing, the model is ground and the surface is polished. After that, the structure can be installed in the oral cavity.

ADVANTAGES AND DISADVANTAGES OF THE METHOD

The advantages of the systems include experts: short production time of the product – there is no need to perform the procedure of removing the impression, which allowed the restoration of the dental unit in one visit to the dentist. In the process of prosthetics, local anesthesia is recommended and only at the stage of preparing the organ for the upcoming implantation of the structure. The exception is the installation of ceramic bridge-like systems of a solid type – they are installed in two visits; the opportunity to see the result in advance on a computer monitor. In addition, the patient can choose the shade that is most suitable in color for natural organs and the doctor will choose the detailed shape of the model; turnkey work. The use of computer programs and modern innovative technologies made it possible to complete all the manipulations on a turnkey basis where previously only a seal was placed during the first visit. The material allows you to mix ceramic elements in the necessary concentrations and get as a result their excellent compatibility, hypoallergenic and high service life; the frame is quite thin – no more than 0.4 mm, which eliminates the need to grind the teeth, they are only slightly ground, creating a rough relief that enhances the adhesion of materials; the absence of darkening in places bordering on crowns, which contain metal alloys; the ability to qualitatively process the seal and the surface part of the enamel so that they will look whole; milling restorations are high wear resistance of crowns, strength and long service life; the ability to adjust and adjust the system; the exclusion of errors. Since the human factor is involved at a minimum in the production process of the part, therefore, the probability of error is practically excluded; high accuracy at all stages of manufacturing the product, which only modern computer technologies can provide; devices made in this way do not cause physical discomfort, do not cause mechanical injury to the soft tissues of the gum and almost do not deform during operation, unlike analog versions made manually.

The technology also has its disadvantages:

not every variant of prosthetics can be performed using this method, and the doctor decides individually how justified the use of CAD CAM is; in some cases, the finished result may differ from the computer version – the systems may differ in color and look not quite natural; the cost of the service is quite high, which limits its use to patients with a low level of income.