Mayka Dental® is a dental software dedicated to the control of machine tools for dental technicians laboratories. The software comes pre-set for YenaDent machines.

Table of Contents

Mayka Dental 6® offer you :

– An intuitive and easy-to-use graphical interface

“L’interface de notre logiciel dentaire vous propose un graphisme épuré (icônes reconnaissables et mémorisables, police de caractères simple et lisible, choix d’utiliser 2 couleurs dominantes : le gris et le bleu) qui participe à votre confort de travail avec une navigation simple et efficace”. Nicolas Lardeau, Directeur de PicaSoft.

– A complete “Wizard” mode

Mayka Dental 6® “Wizard” mode guides you through all the dental preparation preparation processes. Thus, you can be guided step by step for the manufacture of implants, Inlay Core, telescope, or any other type of prosthesis. You can adjust or modify the production solutions. If needed, you can exit the “Wizard” mode to access the advanced setup menus. The “Wizard” mode consists of a menu that offers 17 different functions. The functions are activated according to your choice of prosthesis and material. For example, if you are performing a Core Inlay, only the steps required to produce this type of prosthesis will be available in the “Wizard” menu.

– Custom properties

With Mayka Dental 6® you can define the machining options item by item. For example, you can choose the type of implant connection, the tool diameter for the embrasures and / or the occlusal tables. These custom settings give you the ability to tailor your manufacturing to your requirements, both in terms of quality and productivity. You customize your machining without the need to master a complex CAM.

Benefits of the software Mayka Dental®

- Automatic production (“step-by-step” mode): easily and quickly create a production file, no need for CAM knowledge

- Management of partially machined disks and machining history

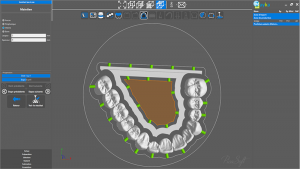

- Automatic detection of the cervical line and high resolution machining

- Machining 4/5 axes positioned and continuous

- Tools dedicated to the machining of zirconia (scale factor, connector for cooking, reduction of fasteners)

- Optimized metal milling with machining recovery and flexible path for high speed machining

- Machining parameters predefined according to the material, the machine and the type of stock

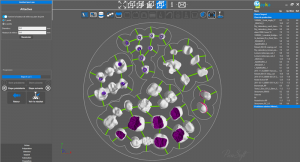

- Fastener management (single and double) for optimization of block filling

- Automatic placement of files to save space

- Tilt of STL files (optimization of the thickness of the blocks)

- Production report and reference engraving on prostheses

- Automatic verification of collisions before machining

- Management of tool changers and auxiliary functions of machines (suction, micro-lubrication, underwater machining)

- Simultaneous 5-axis machining

- Implant libraries

- Implant machining