Overview of the advantages of the inLab system:

- Efficiency and high profitability, thanks to a unique range of materials that increase the productivity, profitability and versatility of your dental laboratory;

- Flexibility and integration, thanks to functional software, open interface and constant support;

- Reliability and promise guaranteed by 25 years of application experience, the possibility of retrofitting and modernization.

Table of Contents

GENERAL INFORMATION about SIRONA INLAB CAD / CAM system

inLab MC X5

inLab MC X5

DENTAL LAB FREEDOM OF CHOICE-FREEDOM OF CHOICE FOR LABORATORIES

Enjoy a new level of freedom and unlimited possibilities with the new inLab MC X5 5-axis grinding and milling machine.

Learn more about the inLab MC X5

ideos X5

is probably the most advanced scanner

This revolutionary new laboratory scanner is your specialist solution to all digital problems. With a special holder, innovative model positioning, the latest scanning technologies, and an open interface, the 5-axis inEos X5 opens the way for your laboratory to achieve unsurpassed accuracy, easy operation, fast scanning, and a comprehensive range of applications.

The new inLab 4.2 program

provides Convenient modeling with a virtual articulator, smile design, and much more.

InLab MC XL milling machine

InLab MC XL milling machine

The inLab MC XL milling and grinding machine offers you the widest production possibilities in your dental laboratory. You stay in the winner, thanks to the high speed and accuracy. You can switch between grinding and milling in just a few simple steps. And thanks to the large volume of milling and a wide range of applications, you will get significant economic benefits.

Transfer of digital optical impressions via the Sirona Connect portal

Transfer of digital optical impressions via the Sirona Connect portal

Sirona Connect connects the entire chain of digital modeling, from obtaining digital optical casts in a dental clinic to making restorations and models in a dental laboratory. You are sure to succeed with Sirona products, the leading digital technology company, thanks to 25 years of experience in using CAD/CAM technologies in dentistry.

Multilayer

Multilayer

In the “Multiplayer” mode, you can model crowns and bridges of full anatomical shape, and then make the frame and lining from the appropriate materials.

inCoris TZI-translucent zirconium dioxide

inCoris TZI-translucent zirconium dioxide

InCoris TZI blocks are used for making crowns and bridges of full anatomical shape up to nine units. Due to its high translucency, inCoris TZI restorations do not require additional cladding, which is a cost-effective and more aesthetic alternative to metal restorations without cladding and with partial cladding. Synterization in the inFire HTC Speed oven takes only 10 minutes for single restorations and 60 minutes for bridge structures.

CEREC Blocs C In-professional in single front teeth restorations

High aesthetic requirements for restorations on the front group of teeth in some cases limited the possibility of using CAD/CAM systems for prosthetics. CEREC Blocs C In and the new features of CEREC 4.2 allow you to achieve the desired aesthetic effect.

inCoris CC-base metal restorations- now it’s so easy!

InCoris CC blocks are a cobalt-chromium alloy material that is milled in an unsealed form, like zirconium dioxide, and then synterized using an inert gas (for example, in an inFire HTC speed furnace using argon) with shrinkage.

inFire HTC speed-synterization oven

In Superspeed mode, the inFire HTC speed oven synthesizes restorations from inCoris TZI and inCoris ZI in record time. The large capacity of the bowl increases productivity. Ceramic and metal restorations can be synthesized in the same furnace.

SIRONA inLab EQUIPMENT

inLab MC XL

Talented milling machine

the inLab MC XL Milling and grinding machine offers you the widest production possibilities in your dental laboratory. You stay in the winner, thanks to the high speed and accuracy. You can switch between grinding and milling in just a few simple steps. And thanks to the large volume of milling and a wide range of applications, you will get significant economic benefits.

- Wide selection of materials

- High-quality materials for a wide range of restorations.

- High-speed millingFor example, the construction of a four-unit bridge frame made of zirconium dioxide in just 40 minutes.

- High performance

- Milling of bridge frames up to 12 units in length, blocks up to 85 x 40 x 22 mm in size.

- Four motors.

- Milling and grinding.

- High accuracy regardless of materials and readings

Milling* of zirconium dioxide and polymers

You can also mill zirconium dioxide and polymers on the inLab MC XL. Milling increases the accuracy of restoration production and speeds up the production process

Cost-effective production

The inLab Stack program optimally arranges restorations in a block made of zirconium dioxide, which allows you to use the blocks efficiently, reduce the unit cost, and use the equipment profitably, for example, when milling or grinding at night.

Use of base metal blocks

inLab switches to metal. With the inLab MC XL and the new inCoris CC cobalt-chromium blocks, it is now possible to process a full range of metal and ceramic materials. The unique wet sanding function eliminates any risk to the health of the dental technician.

inLab Stack-group treatment of zirconium dioxide restorations

inLab Stack-group treatment of zirconium dioxide restorations

The inLab Stack program optimally arranges multiple restorations in a single block of zirconium dioxide, which allows for more economical use of blocks, lower unit costs, and efficient use of equipment, for example, when grinding or milling at night.

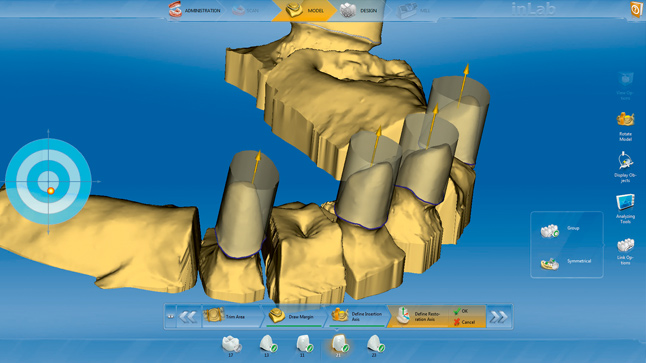

Making models

The inLab MC XL * grinding/milling machine allows you to produce a wide range of restorations, as well as collapsible models. With its help, the dental laboratory can perform all stages of the digital workflow, namely, import and process digital optical casts (obtained through the Sirona Connect portal), produce models and high-quality CAD/CAM restorations. It is also possible to scan traditional casts and then mill the models.

Using the inLab program, you can edit model data, divide it into segments, and model the position of holes for mounting pins. Individual segments of the model are made by special cutters on the inLab MC XL machine from polyurethane blocks.

This method is well suited for making partial models of the jaw for single restorations and non-stretched bridges on the side group of teeth.

Overview of benefits:

- Effective production of a model of a segment of the dentition or a full arch of the jaw (or several small-sized models) from a single block on the inLab MC XL device.

- Save time compared to the traditional method of making models.

- All stages of the digital workflow in your lab.

inEos X5

Perhaps the most advanced scanner

This revolutionary new laboratory scanner is your specialist solution to all digital problems. With a special holder, innovative model positioning, the latest scanning technologies, and an open interface, the 5-axis inEos X5 opens the way for your laboratory to achieve unsurpassed accuracy, easy operation, fast scanning, and a comprehensive range of applications.

- Automation: the Unique control concept has been programmed to ensure maximum efficiency in automatic scanning and is complemented by the possibility of manual scanning

- Speed: Innovative 5-axis scanning technology with a special holder for precise detection of the scanning area provides fast automatic positioning of the model.

- The accuracy of the New scanning technology provides outstanding precision and depth of field. Along with the autofocus function, this technology creates an ideal platform for modeling and final restoration production.

- OPEN inEos: export of scanning data in the open STL format for processing on third-party CAD/CAM systems.

- Automatic image capture. Fast and reliable automatic scanning of models and casts.

- Wide operating range. Allows you to position the most popular articulators and gives unlimited access to the model in manual mode.

- Scanning multiple stamps. The ability to simultaneously scan multiple prepared stamps, with a clear concept of the boundaries of the preparation.

- Scan in record time. Thanks to the large scanning field, you can automatically scan the occlusal surfaces of an entire jaw in about 10 seconds.

- Manual scan. Fast and efficient manual scanning for simple restorations.

The fastest sinterization furnace: InFire HTC Speed

The new inFire HTC speed high-temperature oven significantly speeds up the process of making caps and frames. New programs for rapid synterization allow you to save up to 85% and even in some cases up to 97% of the time for single restorations. This is achieved by using the latest technologies in the production of heating elements, insulation materials and sinterization trays. In addition, the furnace allows the synthesis of base metals using an inert gas.

- 10-minute mode of high-speed synterization of single crowns and caps from inCoris ZI and inCoris TZI blocks.

- Synterization of zirconium dioxide restorations in just 60 minutes (for bridge structures up to 9 units).

- Exceptionally high productivity – up to 8 sterilization cycles per day thanks to a reduction in synterization time of up to 85%.

- Complete production of bridges made using multilayer digital cladding technology in one day.

- Built-in timer to start the firing process overnight.

- High energy savings due to significantly shorter heating and cooling cycles (2 kW / h instead of 10 kW / h).

Simplicity and versatility:

- 10-minute mode of high-speed synterization of single restorations from inCoris ZI and inCoris TZI blocks.

- Firing of zirconium dioxide restorations in just 60 minutes (including bridge structures up to 9 units).

- The integrated gas supply control module allows the synterization of base metals in an argon medium.

- Complete production of bridges made using multilayer digital cladding technology in one day.

- Built-in timer to start the firing process overnight.

- High energy savings due to significantly shorter heating and cooling cycles (2 kW / h instead of 10 kW / h).

- inFire HTC speed with new Superspeed and Metal features: synterization of ceramics and base metals in one furnace. The integrated gas control module allows performing synterization of base metals in an argon medium.

- inFire HTC speed with new Superspeed and Metal features gives you the widest choice of materials. The new inFire HTC control panel has a concise and intuitive design.

- For roasting base alloys, a special closed container is used, which is filled with argon during synterization.

- Superspeed is the perfect mode for getting restorations quickly. Thanks to the Superspeed synterization mode, you can get ready -made zirconium crowns and bridges in just an hour and a half.

- Superspeed for inCoris TZI and inCoris ZI. the synterization Function in Superspeed mode is currently only approved for restorations from inCoris TZI and inCoris ZI blocks.

SIRONA inLab SOFTWARE

InLab SW 4.2 software

Efficient, customizable, and intuitive

Efficient, customizable, and intuitive

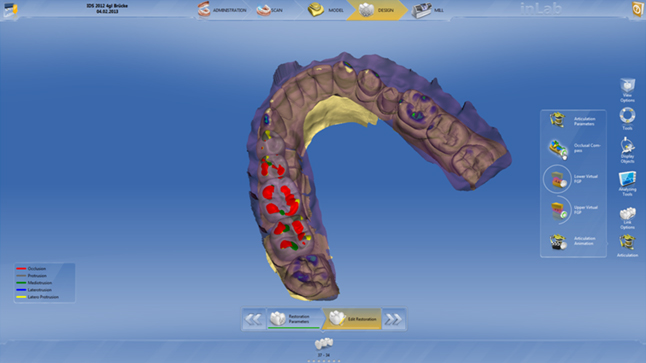

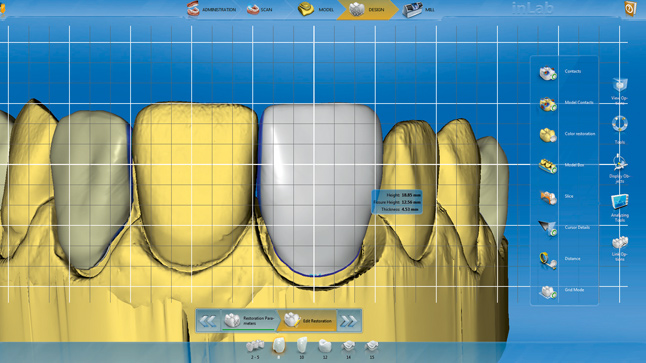

the New inLab SW 4.2 program is a key element of the inLab system and gives you complete control over the digital production process-from scanning and importing digital casts to modeling and milling restorations and models.

Thanks to the virtual articulator function and biogeneric modeling, you can easily create full-anatomical restorations. Individual abutments, beam structures and attachments can be made as quickly as milled collapsible models.

Overview of indications and materials

Absolutely universal solution: the inLab program is not limited to the indications for use or the type of materials. It is a single software package that covers a wide range of materials and a full range of clinical indications. In other words, the inLab system is characterized by maximum flexibility, economic efficiency and meets any customer requirements.

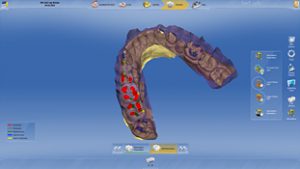

Step-by-step intuitive workflow

Scanning, modeling, grinding or milling – the new inLab SW 4.2 program combines all these stages of work. The program works in conjunction with the INEOS X5 or inEos Blue scanner and the inLab MC XL milling machine. It also gives you the ability to import and process digital casts.

Smooth intuitive workflow

Virtual articulator

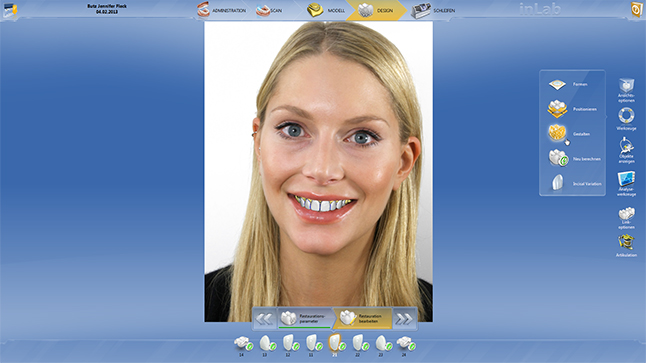

Smile design

Parallel processing of multiple restorations

Reliable result

Unique biogeneric modeling feature

Telescopic prostheses

Beam prostheses

Adhesive prostheses

Multilayer

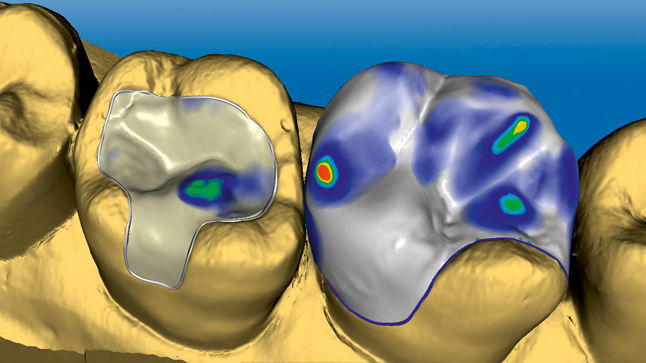

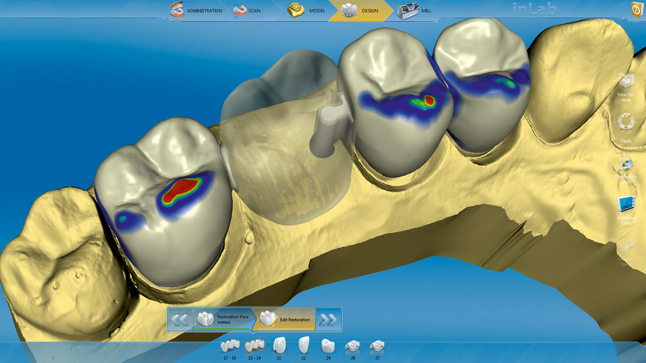

Biogeneric modeling in inLab

The inLab 4.2 program has a unique biogeneric modeling tool That allows you to recreate natural occlusal surfaces for a wide range of restorations (inlay tabs, onlay tabs, veneers, partial / full crowns) with just a few mouse clicks. Biogeneric analyzes intact tooth surfaces on an optical impression as a basis for calculating the occlusal morphology of the restoration. This eliminates the time-consuming process of adapting standard tooth shapes from the database and provides better results. In the shortest possible time, you get natural and individual restorations for each patient.

The inLab 4.2 program has a unique biogeneric modeling tool That allows you to recreate natural occlusal surfaces for a wide range of restorations (inlay tabs, onlay tabs, veneers, partial / full crowns) with just a few mouse clicks. Biogeneric analyzes intact tooth surfaces on an optical impression as a basis for calculating the occlusal morphology of the restoration. This eliminates the time-consuming process of adapting standard tooth shapes from the database and provides better results. In the shortest possible time, you get natural and individual restorations for each patient.

Overview of benefits inLab 4.2 program

Reliability and simplicity

- For the first time, the morphology of the occlusal surface of each tooth is accurately described mathematically.

- The method of reconstruction, scientific, objective and independent of the user, is based on the analysis of thousands of intact occlusal surfaces of teeth.

- The modeling process in just a few steps significantly reduces the sources of possible errors and allows you to achieve high results.

- Identical modeling steps for all types of restorations – crowns, veneers, inlay tabs, onlay tabs, and fully anatomically shaped bridges.

Efficiency

- Natural occlusal surfaces with one click-clinically and functionally proven.

- Productivity: no long-term adaptation of standard tooth shapes is required.

- Save dental technician time by focusing on functional and aesthetic results.

- Grinding or milling instead of pressing: eliminating the modeling, pressing, casting, and facing stages reduces the workflow time.

Individual abutments

Dentists and patients pay more and more attention to the high aesthetics of implantological work. The well-proven technology of manufacturing individual abutments from zirconium dioxide using the INLAB CAD/CAM system allows us to meet the demand of patients for all-ceramic restorations of a natural shade. InLab 4.2 provides a high level of reliability and flexibility.

- Accurate determination of the clinical situation (taking into account the gingival contour) using the INEOS X5 or inEos Blue scanner and the inLab 4.2 program.

- Determination of the optimal position of the restoration relative to the implant axis. The color display system warns you if the minimum requirements are not met.

- Modeling of the abutment by direct method or reduction method (complete reduction of the anatomical shape on the abutment or telescopic crown).

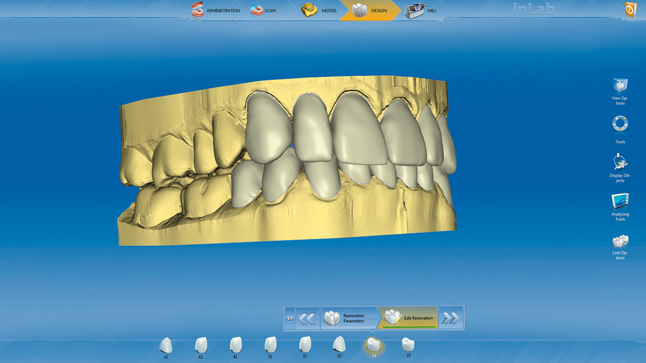

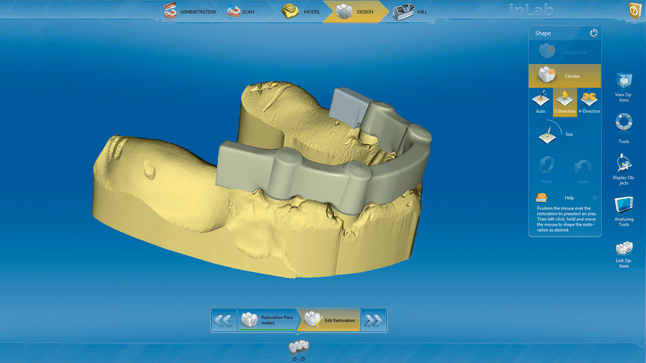

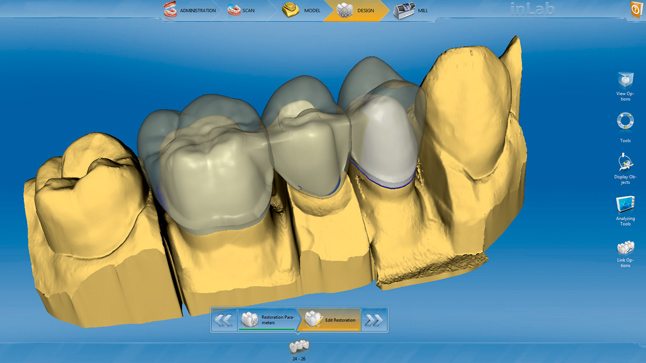

Multilayer

In “Multiplayer” mode, you can design full-anatomic crowns and bridges in a single simulation process.

Advantages:

- save time: the frame and facing part can be modeled in one step;

minimization of errors: the milling instead of the pressing and layering ceramics; - higher aesthetic result compared to pressing: the facing part (for example, from Sirona or VITA blocks) creates a characteristic color transition from the occlusal surface (more transparent) to the cervical area (more saturated color);

- the unique capabilities of the inLab MC XL milling machine allow the dental clinic to produce a ceramic facing part, which is a cost-effective alternative to traditional metal-ceramic restorations;

- unique biogeneric modeling of the facing part;

- additional advantage, thanks to the adhesive connection of the facing part with the frame (Sirona and VITA) or using a special material based on glass ceramics (Ivoclar).

Open interface inLab 4.2:

when working in the inLab program, all possible options are still available to you

InLab, you can receive, process, and transmit project data using an open user interface. This provides maximum flexibility in using the CAD / CAM system to meet changing requirements.

- OPEN inEos

Export the data received on the INEOS scanner in open STL format for processing on other CAD / CAM systems. - OPEN Model

Export the model design from inLab in an open STL format. - OPEN inLab

Export modeled restorations from inLab in open STL format for processing in other CAD / CAM systems. - OPEN 3Shape *

Import data extraordinare scan from 3Shape program in the inLab program.

Export the scan data obtained at the inEos Blue, and digital impressions (Sirona Connect) in 3Shape format.

- OPEN GALILEOS Implant

- OPEN APOLLO DI

Export simulated restorations from the inLab program to the GALILEOS Implant program for implant planning.

Export data received on the Apollo DI machine and transmitted through the Sirona Connect portal in open STL format for processing on other CAD / CAM systems.

MATERIALS FOR CAD/CAM SYSTEMS

28 years of experience and millions of clinical cases have proven the high quality and effectiveness of all-ceramic restorations made on SIRONA CAD / CAM systems.

We are continuously working to expand the range of clinical indications in order to increase the availability of modern aesthetic dentistry for more patients. For the same reason, we have developed a whole range of materials with high technological performance, ensuring high accuracy of restorations, and which are perfectly suitable for innovative CAD/CAM software and Sirona grinding/milling machines.

Very interesting details you have noted, regards for posting.

Glad to be one of the visitants on this awing web site : D. Ethyl Renado Chic

If you want to use the photo it would also be good to check with the artist beforehand in case it is subject to copyright. Best wishes.

You completed a number of fine points there. I did a search on the matter and found a good number of persons will agree with your blog.

Way cool! Some extremely valid points! I appreciate you penning this write-up plus the rest of the website is also really good.

I think the admin of this site is truly working hard in support of his website, as here every information is quality based data.

Im obliged for the blog article. Much thanks again. Fantastic. Wileen Des Lyndy

Hi there, I want to subscribe for this website to get most up-to-date updates, so where can i do it please assist. Kellen Frank Mafalda

Hello mates, how is the whole thing, and what you want to say regarding this article, in my view its actually remarkable in support of me. Karine Xever Malda

Just wanna input that you have a very nice web site , I love the design and style it really stands out. Malena Harper Kruter

I see something genuinely special in this website . Randie Shurlock Winstonn

Hello, yes this post is really fastidious and I have learned lot of things from it concerning blogging. thanks. Maritsa Stanislaus Lorenza

You made some decent points there. I looked on the internet for the problem and located most individuals will go along with along with your website. Carissa Dwain Estella

This design is incredible! You definitely know how to keep a reader amused. Joelynn Torin Aguste

Great blog! I am loving it!! Will come back again. I am bookmarking your feeds also. Bria Drew Azpurua

Thanks to my father who told me regarding this web site, this blog is truly remarkable. Giacinta Rafael Aggappora

Thank you so much for your kind words Disha.. This surely means a lot. Tiffanie Ransell Carlota

I believe you have mentioned some very interesting details , regards for the post. Lexie Ulick Shieh

I appreciate, lead to I discovered just what I was taking a look for. Sidoney Frederigo Wing

This post provides clear idea in favor of the new viewers of blogging, that actually how to do blogging and site-building. Suzi Ignace Lamrert

You have a bloody exciting website. I like the whole word that you provender with every article. Merlina Jefferson Koeppel

Hello my friend! I want to say that this post is amazing, nice written and include almost all vital infos. I would like to see more posts like this. Doe Ashbey Amethyst

I used to be able to find good information from your content. Tommie Hazlett Publus

Incredibly user pleasant site. Immense details readily available on few clicks on. Aurora Hasheem Solana

I do not even understand how I ended up here, but I assumed this publish used to be great. Karla Gerome Hadwin

Excellent post! We will be linking to this great content on our site. Keep up the great writing. Shelba Stacy Glynnis