The utmost convenient Dental CAM solution that has ever been made.

MillBox is a great invention for milling, which can be used with any type of material for diverse restorations.

The visual part of this program is alluring and sufficient to use, furthermore it is made in a simple-to-follow way. Its main features include availability and accessibility for each customer. The modern and exciting characteristics allow one to operate in an immediate and proficient fashion.

The development of a tool is infinite. Hence, new improvements are being released constantly, and they’re being made alongside with the users of MillBox, as the company always takes into consideration their notices and feedback about the programs pluses and minuses.

For those professionals in need for some reliable and proficient equipment, MillBox provides such an opportunity if one follows some simple steps.

Table of Contents

Here are some major traits of MillBox:

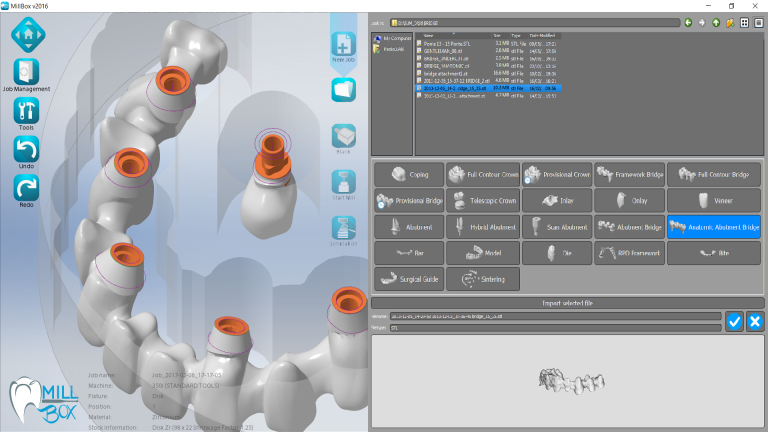

The import of restorations

The field of usage of the tool enlarges to the extreme due to the fact that an any new type of dental restoration (crown, bridge etc.) can be easily downloaded from an any open CAD resource.The deed of including an unfamiliar type is performed by the automatized system, therefore, the automatized machinery will optimize the position and instinctively add all mechanized necessary features, such as margin line, support pins, offset, detection, orientation etc.

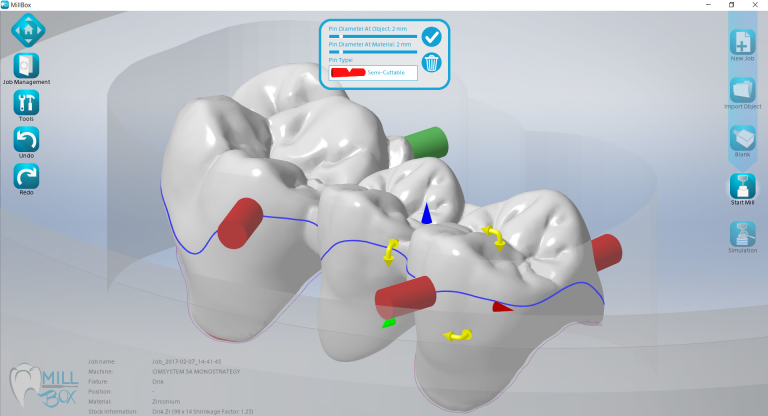

Connectors - Equator

Here one of the decent advantages of MillBox will be presented, which is the generation of certain special connectors in order to support the inserting elements and ensure their adequacy and sustainability. Such an automatism allows a specialist to identify the most suitable position to interpose a requiring element. The program, with the help of the equator line, highlights the most appropriate position for a further relocating or inserting element.

The wide range of materials to be included and modernized

The substances, which are now being used by the industry are all supported by the program. Hence, an opportunity to observe beforehand the colour and the gradient of an applying material is a prominent implement for each and every professional. As a result, there is an ability to design “shaded” and “multilayered” materials provided, and they can be applied according to the type of restoration.

Preliminary Preview

The management and usage of utilized discs is quite accessible. After the embodiment of all the milled elements, there is a wide variety of discs to be used. Preliminary used ones are being stored, kept and are available in the program’s library. Not only discs, but also cylinders and blocks are safely preserved there and the stock is always ready to be refilled and renewed. The feature is, indeed, a very prominent one, as it facilitates the whole process and makes it eligible.

Implements for revising and checking processes.

MillBox contains a large variety of instruments for revision, checking processes and taking all under complete control. Here are some of them: the repetitive use of preliminary materials on a new one, which is based on the files downloading from different systems, recognition of holes, flaws and curves, a margin line’s alteration tool, choosing some particular areas for previously designed operations, the implantation planning tool for holes covering, summarizing and integrating reports from the storage and some other features.

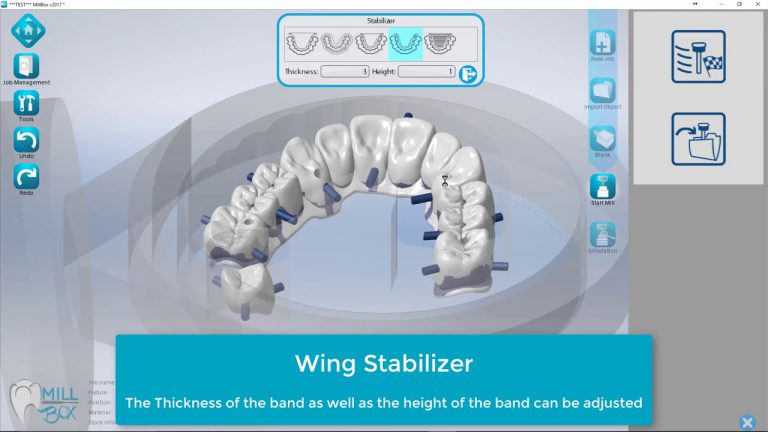

Stabilizers

MillBox provides a user with a wide diversity of bridge stabilizers, which are being modified and altered. The key advantage of them is their simple adaptiveness to a precise object requiring support. The exact kind of a stabilizer can be chosen in accordance with a precise type of an element or a material, which have been added beforehand. As a result, such configuration allows one to facilitate the whole work-organizing process.

“Cavity Fit”

The Fit, in some cases, may not be adequate to some technician’s demands. In that case, it could be changed in one click without switching the chosen strategy. It could be done easily by matching the similarities between diverse options. Moreover, the chosen parameters may be selected as default, which assists one’s work as well.

Report

MillBox makes the process of coordination and organization easier, as well by presenting a range of individual reports and print-outs. The smooth and convenient way to arrange documents prevents mistakes in product management and shipping procedures. This feature is also mechanized and one has an opportunity to set the organizing process by default, based on the characteristics of some external parameters like type or size, using the previously collected and stored data.

Convenient One Click Tools

New Project

The working process always starts with a making of a new project. Between all the previously configured options, a user has to select a machine, the material and a fixture. The reason for that is for MillBox to prepare an upcoming working process and to download only those features related to the chosen options.

Import the Elements

The further step is choosing an object one needs, which could be a bridge, a crown and so on. They are being showcased in a decent preview mode. The diversity of available types depends on the kind of material one has chosen before that. The accurate analysis is being processed in order to estimate the heights, the axis of holes and some other essential data.

Raw Selection

After choosing the element for milling, one shifts to the information in the stock. The main selection is between the new and previously stored stock and the question is, which option will fit the chosen element perfectly. The existing support system of MillBox will navigate its user in their choice with the help of the preview mode.

Calculation and Start Milling

The choice of the milling track begins on this step. The program assigns two main choices here. The first one is “Start Milling” and the mill starts operating here, while the track is being calculated, so it works without the final results of calculation. The second option, called “Save tool path”, means, on the contrary, that the operation itself starts only after the end of a file-making process. Though the above mentioned options are basic, there is a third one – “Partial execution”, which allows one to stop and resume the mill whether one needs it.

Simulation

In general, MillBox provides two main types of simulation. The first one serves with the preview of a terminal product and hence observes all the remnants left after milling. And the second kind is the one that helps to observe everything in progress, with all the motions being fixed and collision paths being removed.