Komet Dental buy online

Journal “Modern Orthopedic Dentistry”

7 April 20153956

Orthopedic dentistry, CAD / CAM technologies

Technologies

CAD/CAM, 3Shape

BadPoorAverageGoodGreat

Dmitry Filinov,

Head of CAD / CAM Technology Department

, RIKOM Group of Companies

Digital technologies in dentistry are steadily replacing traditional methods of obtaining casts and working models. A modern intraoral scanning system must meet the following basic requirements:

- High accuracy of digital casts, which ensures high-quality storage of restorations.

- Instant quality control of the preparation and digital impression.

- No additional manipulations with the restoration when fixing the work.

- Exclusion of impression material and scanning powder from the workflow.

- Speed in the process of obtaining digital casts and no need to re-scan.

- The possibility of making work without plaster models.

- Comfort for the patient (reduced visits to the doctor, reduced reception time, comfortable and fast scanning, high clinical results).

- Mobility and ergonomics of the intraoral scanner.

- Convenient ways to communicate with laboratories.

- Improving the competitiveness of the clinic.

Table of Contents

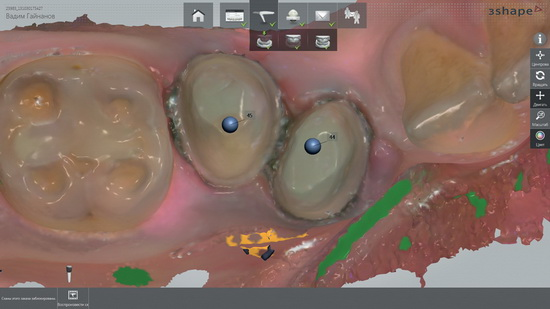

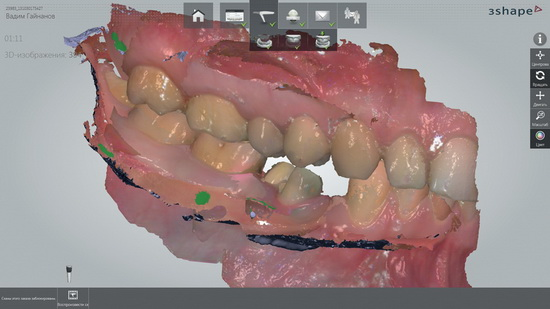

The TRIOS Color POD intraoral scanner from 3Shape fully meets these requirements and at the same time has a number of competitive advantages, the main of which is scanning in color. Due to the visual separation between the soft and hard tissues of the teeth, the software can automatically determine the border of preparation, which, if necessary, the dentist can change manually.

Receiving high-quality digital casts in natural color with TRIOS Color POD, the doctor can clearly demonstrate the patient’s oral situation and offer options for orthopedic treatment.

The production of an orthopedic structure in many cases still requires the creation of a working model. Until recently, it was possible to make a high-quality collapsible plaster model only in the conditions of a dental laboratory. But thanks to a new solution from 3Shape-the Model Builder program-dentists have the opportunity to virtually create collapsible working models of the highest quality based on digital casts obtained from the TRIOS Color POD, without leaving their workplace.

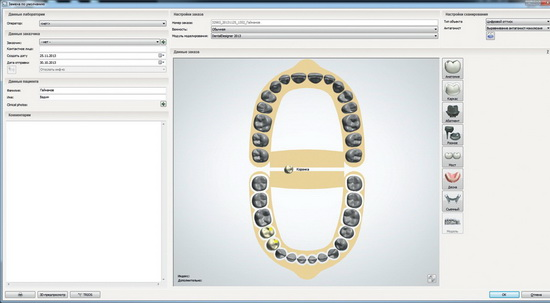

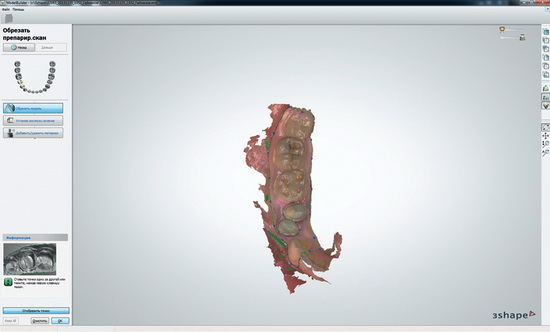

The process of creating a working model is very simple. Digital impressions obtained from TRIOS are automatically imported into the Dental System modeling program from 3Shape. In it, first of all, a project for future restoration is created.

At this stage, it is very important to correctly specify the type and material of the future structure, because if there are errors at the stage of creating the project, errors will inevitably appear at the subsequent stages of creating models and restorations.

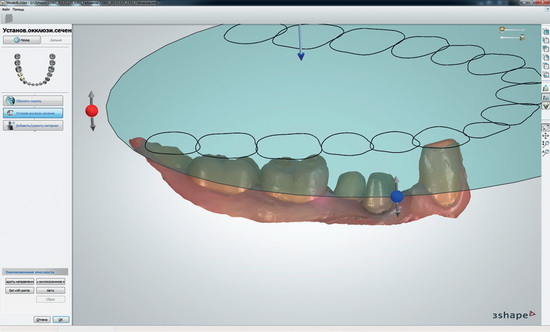

After creation, the project is transferred to the Model Builder program. Working with this program is a sequence of steps, in stages, the doctor has the opportunity to:

HIGHLIGHT IMPORTANT AREAS,

ADJUST THE OCCLUSAL POSITION OF THE JAWS,

EDIT THE LEDGE BOUNDARIES.

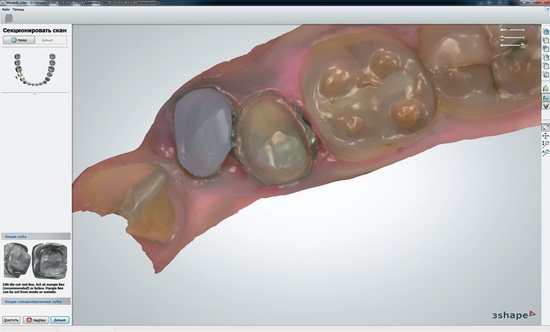

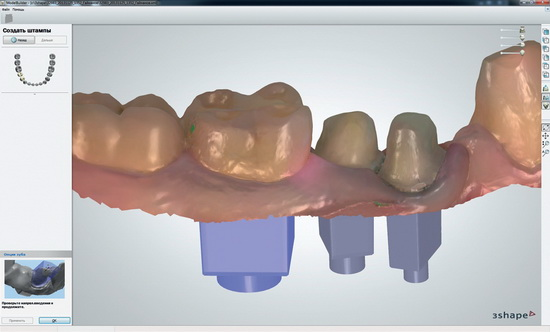

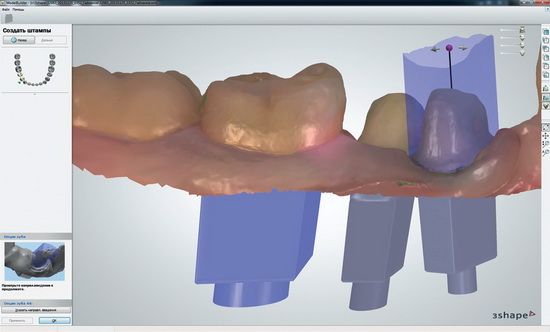

Next, the doctor determines the stamps of the collapsible model, marks the working and additional teeth, and sectionalizes them.

In the Model Builder system, there are many options for partitioning collapsible models and adjusting the position of the stamp, even with high complexity and large divergence of teeth and implants. When setting the axis of the stamp position, it is desirable to be guided by the axis of the position of the sectioned tooth.

The virtual creation of the model is completed by the stage of substituting the basis and the model lock for the articulator.

The virtual creation of the model is completed by the stage of substituting the basis and the model lock for the articulator.

The 3D model can be saved in STL format and made using any open CAM system.

The 3D model can be saved in STL format and made using any open CAM system.

Thus, the 3Shape TRIOS Color POD intraoral scanner, supplemented with the Model Builder program, provides dentists with the widest opportunities to create digital working collapsible models, eliminating the need to apply for such services in laboratories or milling centers. The obvious time savings compared to traditional methods of making models and the ease of working with this system are the keys to its maximum rapid development and implementation in practice.

Thus, the 3Shape TRIOS Color POD intraoral scanner, supplemented with the Model Builder program, provides dentists with the widest opportunities to create digital working collapsible models, eliminating the need to apply for such services in laboratories or milling centers. The obvious time savings compared to traditional methods of making models and the ease of working with this system are the keys to its maximum rapid development and implementation in practice.