Thanks to its user-friendly, innovative and attractive interface, MillBox simplifies the process of arranging restorations in the material and creating a tool path. New users can very quickly begin to perform layout operations, even without special training or with minimal training. MillBox is built on a powerful CAM platform that is very easy to use and minimizes the time spent on processing orders. And this, in turn, provides laboratories with a significant return on investment in digital technologies.

Table of Contents

MillBox is thoroughly designed for the dental industry and is a reliable partner, improving the laboratory workflow and increasing the quality and range of work.

MillBox also allows you to enter data using the touch screen, which makes it much easier to work with it.

Using MillBox means:

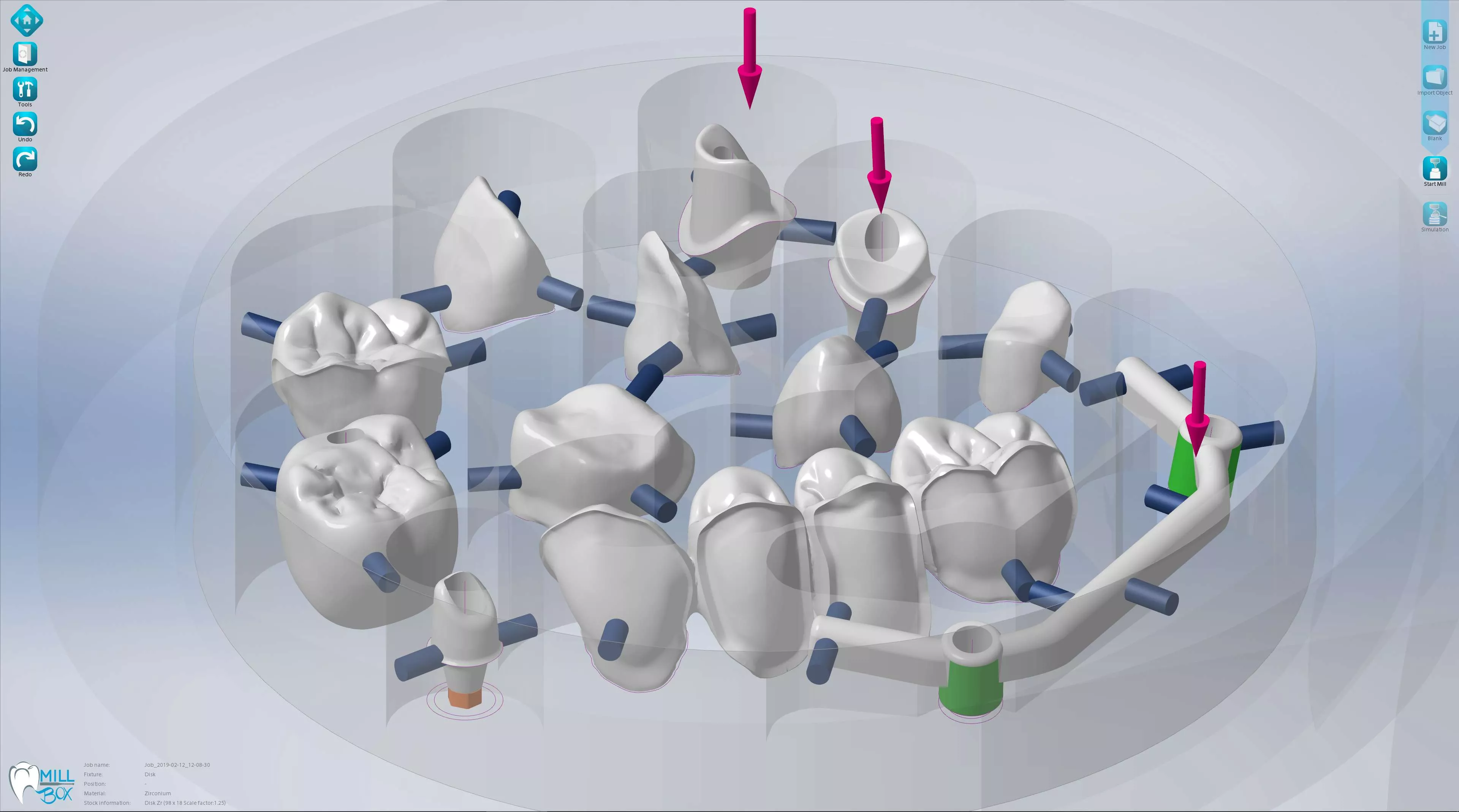

One “click” allows you to perform any actions with restorations: rotation, positioning, changing the positioning and / or adding an additional support pin.

New graphical user interface with full support for touch displays.

Users intuitively prepare the work for milling.

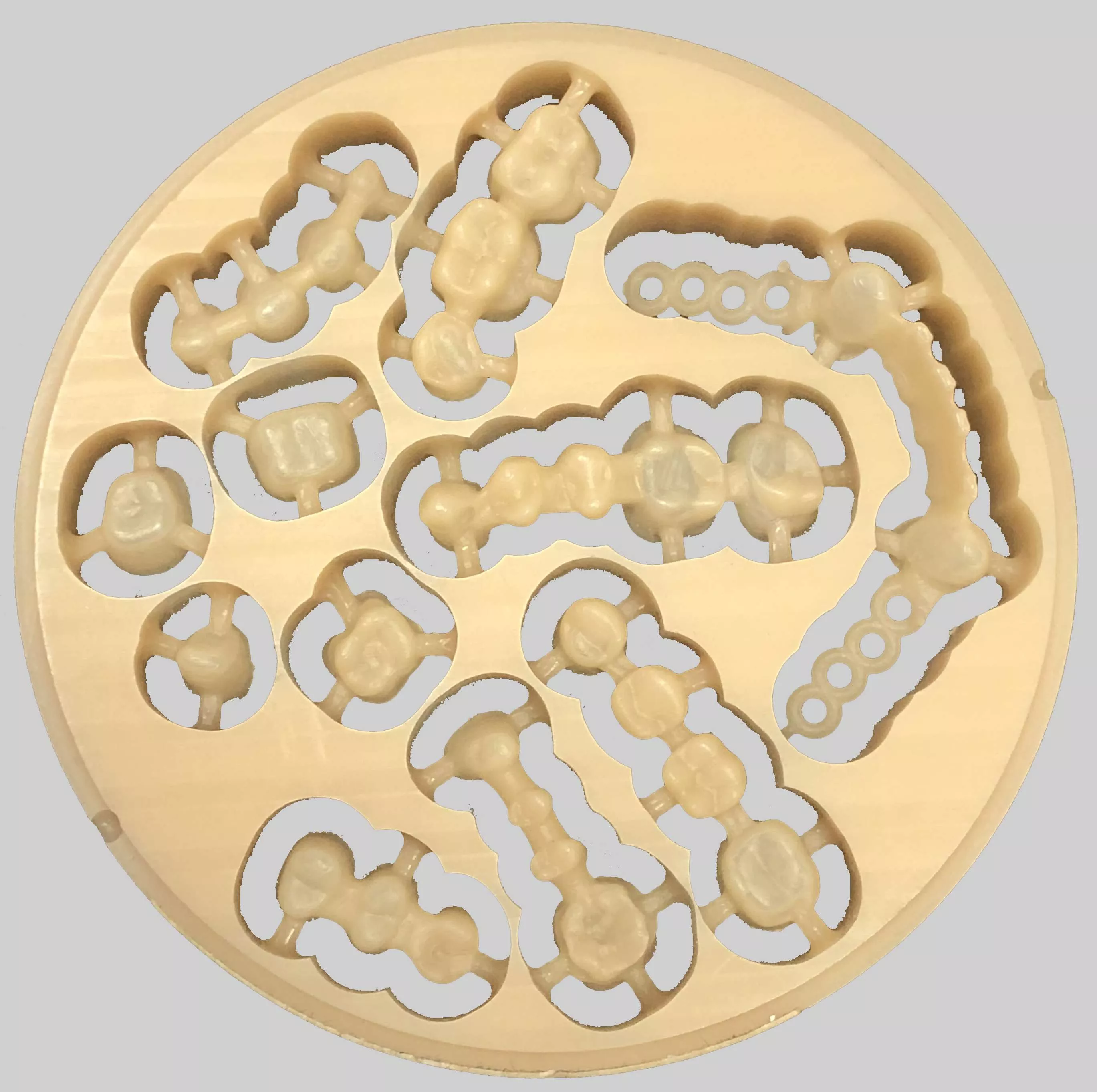

The laboratory can perform any restorations from any materials.

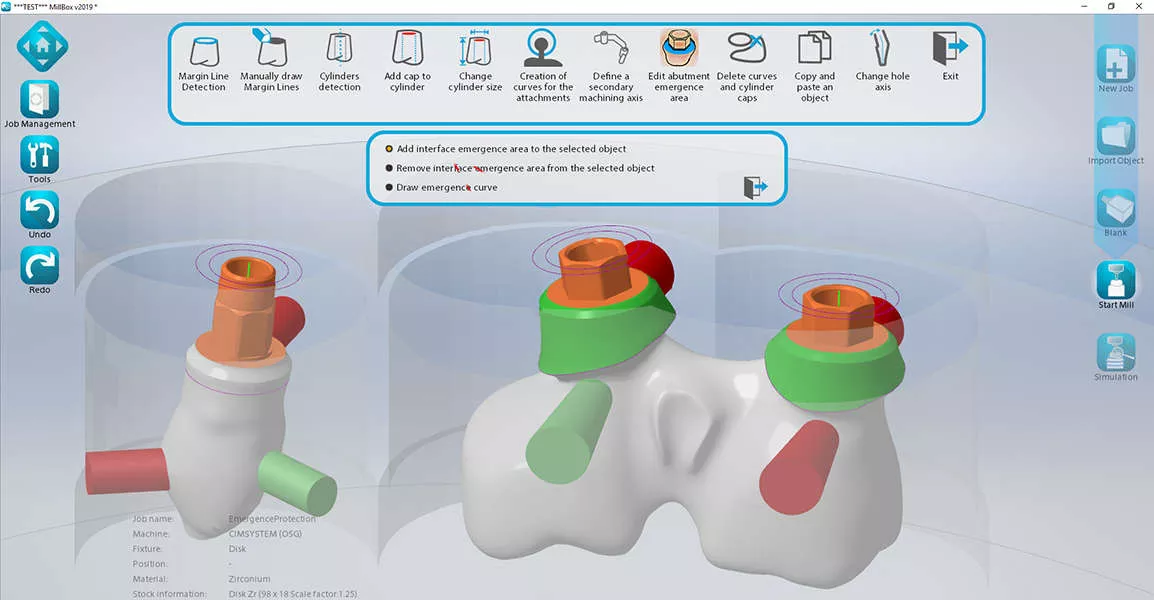

MillBox has different colors to highlight areas that may require additional attention during milling (undercuts or inaccessible areas). MillBox also informs the user in case of problems with the positioning / rotation of the parts.

MillBox is specially designed for professionals who need simple but effective tools. The user performs the work more productively, in a short time, and performs fewer actions.

Thanks to the continuous improvement of the software, MillBox users always work at the level of modern requirements.

The software is becoming even more accessible: over the past year, new features have been added and existing ones have been improved.

Among the new features is the Cavity Fit feature. Sometimes, after a long process, the milled element may have a poor fit due to problems with the design or material. With the MillBox program, you can simply” click ” to adjust the stock at the preparation stage, without changing any cutting strategy. These parameters can then be used by default each time a similar item is imported.

Five new types of Stabilizers were introduced in MillBox. Each of them has its own structure that can adapt to the type of object you want to support.

MillBox allows you to open different work sessions at the same time. The Windows taskbar displays a “Progress Bar” that indicates the progress of the calculation. If an error occurs, this panel turns red to alert the user.

All materials currently used in the dental industry are fully supported by MillBox. We also offer the ability to change the display color of the material that is used. We can use and display “shaded” and “layered” materials. Restorations specifically placed in materials during the design phase can be automatically imported into MillBox, while maintaining the position between CAD & CAM.

A new add-on module, Make & Mill, was introduced so that two different production technologies could be used in the same software: additive and subtractive. The user can import the STL of the object to be laser-sintered at a reduced cost, and then transfer the indexed part to the milling machine so that only the designated key sections are milled if they need more precise processing (as is the case with the panel interfaces).

In addition, in MillBox, you can import any type of dental restoration from any open CAM source. With 3Shape®, DentalWings®, and Exocad® software, type and morphology recognition is fully automated.

Automatic functions are applied to each imported object, such as: layout, support pins, split line detection, offset, and orientation.

Now more than ever, MillBox is the best partner to improve your workflow, improve the quality and increase the range of your products.

CIMsystem, thanks to its extensive manufacturing experience in the dental industry, fully supports its customers. From the initial assessment of their needs to the implementation and configuration of the right solution, the company delivers high-quality, innovative and powerful technical tools, provides training by qualified technicians and excellent after-sales service and support.

Purchasing this software directly from the manufacturer or its authorized representatives is a guarantee of efficiency and productivity, as well as reliability and competence. There are inauthentic versions of software on the web that offer unauthorized and unverified sources. The use of non-certified products implies poor performance of the software and incompatibility with the hardware used.