Currently, a dental prosthetics system called CAD/CAM is widely used in dentistry. It stands for Computer Aided Design Computer Aided Manufacture — design and production is performed using a computer. In other words, the CAD/CAM system is a complex for digital design, modeling and subsequent automated manufacturing of products according to specified parameters. Computer technologies are used for the manufacture of dentures at all stages.

CAD / CAM allows you to make denture frames from zirconium, glass ceramics, cobalt-chromium, titanium and other various alloys. A pre-modeled blank formed with the help of special computer programs is processed on special milling equipment with software control, which allows you to achieve the highest manufacturing accuracy and take into account the anatomical features of any patient.

Currently, cadcam systems are presented in a wide range, made by various manufacturers.

Table of Contents

The stages of manufacturing orthopedic structures using a CAD CAM system.

In the manufacture of orthopedic structures, the process is divided into the following stages:

- Scanning of the oral cavity;

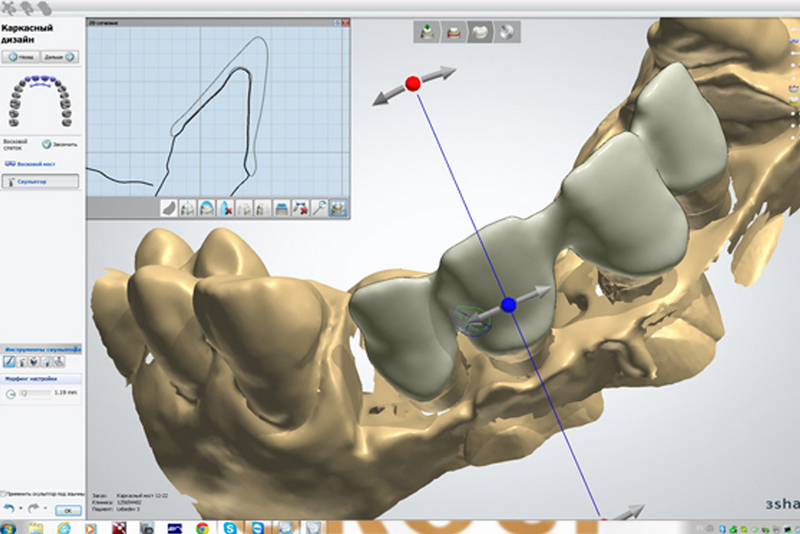

- 3d modeling of orthopedic structures;

- milling of the workpiece;

- stamping, soldering, casting;

- grinding and polishing of the workpiece.

Advantages of the CAD / CAM system in comparison with the “classic” production of structures.

The indisputable advantages of the system include:

- High accuracy of manufacturing products — the absence of shrinkage, deformation of the material, ensuring the highest quality of the finished product, fully corresponding to the specified parameters;

- The ability to take into account the needs of any patient — The possibility of manufacturing objects of any complexity and configuration, including hollow ones;

- The possibility of manufacturing prostheses from zirconium dioxide;

- Minimum production time of dental structures-visualization of intermediate and final results, their coordination with the patient allows you to start the manufacturing process in the shortest possible time;

- Fully automated manufacturing process, eliminating the human factor;

- Compact installation dimensions.

Orthopedic structures manufactured using CAD/CAM technology

CAD/CAM technology allows you to make removable and non-removable models of prostheses, as well as products of other directions, in particular, surgical templates. However, despite the presented functionality, CAD/CAM is most widely used for creating non-removable orthopedic models:

- veneers;

- tabs;

- crowns made of solid ceramics and zirconium;

- bridge-like structures;

- telescopic crowns;

- temporary crowns that require production in the shortest possible time.

- individual abutments during implantation.

Disadvantages of the CAD/CAM system

Currently, the CAD/CAM technology is practically devoid of disadvantages. The technology is constantly being improved, new technologies are emerging that allow performing more complex orthopedic structures and finding applications in new areas. The main drawback of using the CAD/CAM system is the high cost of the finished product, which is almost 2-3 times higher than with the “classic” design.

Classification of CAD / CAM technologies.

All CAD / CAM systems are divided into two types:

- “Closed systems”;

- “Open systems”

“Closed” systems include such equipment that can only work with certain consumables, usually produced by one company.

Open CAD / CAM systems have a number of advantages for users:

- Selection of any CAD / CAM materials from the range available on the market for milling finished restoration;

- The scanner for digitizing the impression or the remaining substance of the tooth, as well as the milling machine, are selected by the operator. That is, the images obtained by the clinician using an intraoral scanning camera of one open CAD/CAM system can be freely used for modeling in the software of another open system and milled on the machine of a third open system of another manufacturer.

According to the second main classification, all CAD/CAM technologies are divided into:

- medical services;

- laboratory tests.

The best manufacturers of CAD/CAM systems.

Dyamach

is a modern design from an Italian manufacturer. It is distinguished by increased accuracy and the ability to work and combine different materials. A milling machine that grinds products in a continuous mode reduces the operation time. The disadvantage of the system can be considered its high price in comparison with analog versions of other manufacturers of competing brands.

Roland

is a product of Japanese developers, the main advantage of which is the absolute noiselessness of the milling machine during the grinding of the product. There is also an increased accuracy in processing and giving the necessary shape to a prosthesis made of materials of increased hardness, for example, crowns made of zirconium. The disadvantage is the high price of the equipment, which limits its use in domestic dental clinics.

Sirona Dental Systems

is a representative of German manufacturers. Like everything made in Germany, it is distinguished by high quality and compliance with all the requirements of standards. It belongs to the equipment of the average price group. The devices are widely used in Russian dental centers. The ideal solution for clinics with low traffic and the presence of modern laboratories.

Zirkonzahn

Has the highest productivity-about 1000 units of models per month. Compatible with intraoral scanning devices. Processes any materials. It refers to a product of the middle price segment. On the European market since 2009. A product of Swiss manufacturers.

WIELAND

The Wieland milling machine has a massive chassis and a solid granite work surface. Designed for use in large laboratories and milling centers. The main advantage is the built-in high-quality liquid crystal screen, which allows instant image output during the grinding of the material. It is equipped with an autonomous exhaust mechanism.