Although digital software-controlled machines, which are the basis of CAD/CAM, have been used for a long time, they are not so common in dentistry, but they are taking an increasingly solid and worthy position.

Table of Contents

CAD / CAM stands for Computer Assisted Design/Computer Aided Manufacturing

– computer-assisted design / manufacturing. This is the most modern technology for the production of denture frames using computer modeling and milling on numerical control (CNC) machines.

CAD / CAM technology makes it possible to obtain dental prosthesis frames of the highest accuracy, excellent biocompatibility and impeccable aesthetics with high automation of work.

The goal of computer design

The goal of computer design

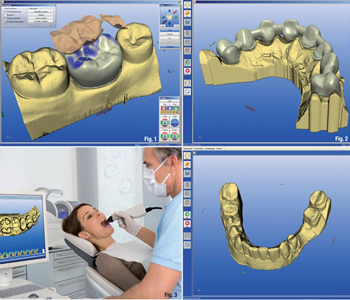

is to eliminate inaccuracies as much as possible, to see a full-fledged model of the denture in advance, in order to best plan the process of prosthetics. Thanks to computer modeling, you can see what your appearance will be like with new teeth even before you start working, and choose the best option for the appearance and installation of the prosthesis.

With the help of CAD / CAM systems,

you can make single crowns and bridges of small and large length, telescopic crowns, individual abutments for implants, recreate the full anatomical shape for models of press ceramics applied to the frame( overpress), create temporary crowns in full profile and various injection models. The material can be zirconium dioxide, titanium, cobalt chrome alloy, plastic, wax.

Compared to casting

– the traditional method of manufacturing frames (creating a wax composition, preparing the mold, casting, unpacking, processing and storing), CAD/CAM technology does not require such high qualifications and extensive experience of the technician, does not take up so much working time and space. There is no contamination of the working area when using CAD/CAM equipment, as in casting. In principle, a CAD/CAM complex can be serviced by a single technician.

The special advantages of the CAD / CAM process include:

- the highest manufacturing accuracy (size deviation of 15-20 microns in comparison with 50-70 microns in casting)

- a high level of automation of labor (saving the working time of the technician more than five times)

- high productivity (up to 120 units). per day)

- the possibility of modeling at the workplace, and milling – in a remote milling center

- a wide range of materials, compact equipment (CAD / CAM-complex occupies a room with an area of 10 square meters. m).

Technological scheme for manufacturing a frame made of zirconium dioxide in a full-cycle CAD/CAM milling center:

- The plaster model is fed to the milling center.

- The plaster model is scanned using a special device (scanner). The scanner converts the information about the appearance of the model into a computer file. Then, using a special computer simulation program (CAD module), a frame, abutment, suprastructure, etc. is constructed on the model. The program offers a design, and the technician can change it with the movements of a computer “mouse” in much the same way as a wax composition is made on a plaster model with an electric spatula.

- In addition, the design can always be viewed from any angle, “remove” from the model, try options for cladding, consider any cross-section. The result is an optimal frame design.

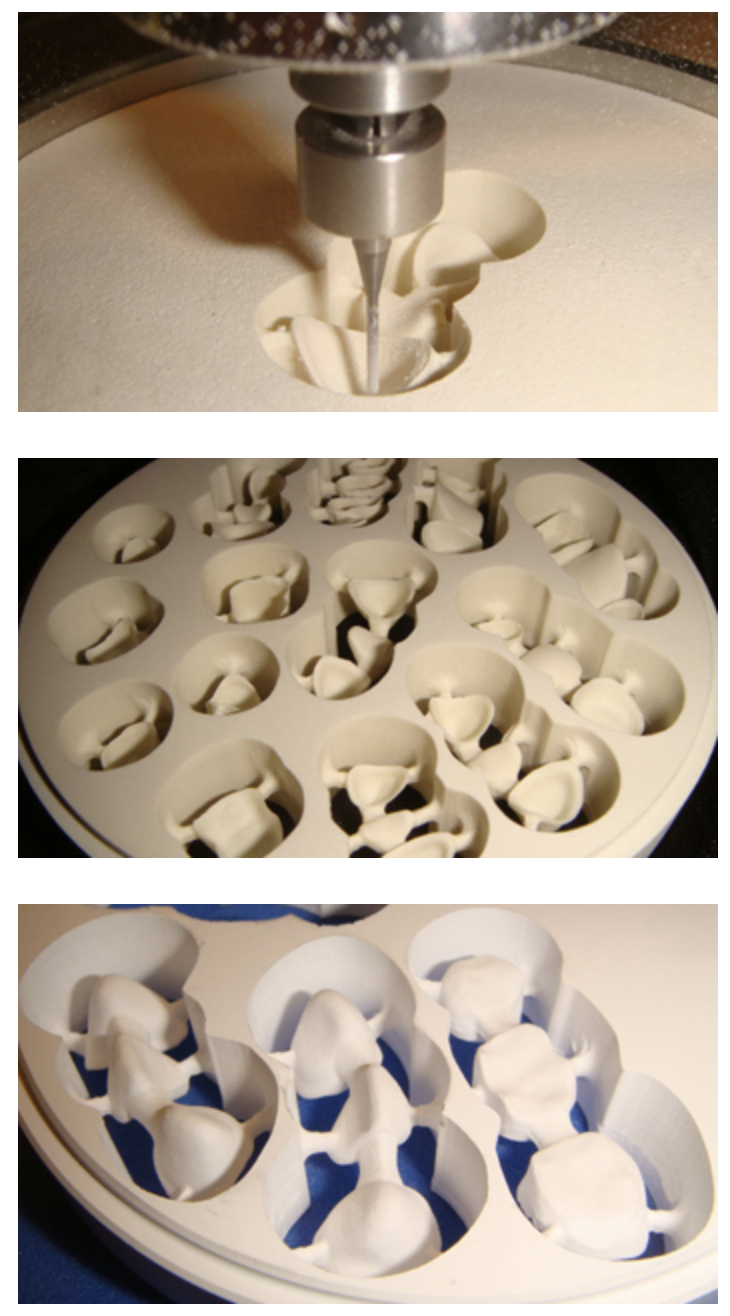

- After the simulation, the design file is sent to the control unit of the milling machine. Depending on the selected material, the milling machine saws (mills) the frame from the workpiece. As a result, the material embodies a three-dimensional model created earlier on a computer. If the material chosen is zirconium dioxide, the structure needs sintering (agglomeration) after milling.

- The frame made of zirconium dioxide is placed in a special sintering furnace, in which it acquires the final size, color and strength.

- The robust, aesthetic, precise and lightweight frame is ready.