hyperDENT offers you all the prerequisites for quick reaction to all dentistry challenges in cost efficient way and in time. Below you will find out why this system is the best solution among systems offered by cimoetitors.

Table of Contents

Types of hyperDENT versions

One may choose the hyperDENT version that suits best to his or her needs:

hyperDENT Classic or hyperDENT Compact.

And as an open system, it ensures great flexibility as follows:

– In raw materials used

– In building the specialized manufacturing environment (e.g. milling machine)

– When using milling tools

– While transferring data from other systems

– For all strategies – from 3D machining to milling, right up to 5-axis simultaneous machining

Types of hyperDENT versions

One may choose the hyperDENT version that suits best to his or her needs: hyperDENT Classic or hyperDENT Compact.

HyperDENT Classic

HyperDENT Classic comprises all functions required for large laboratories. The function of multi-part roughing contributes to the workflow efficiency through material waste reduction, tool service life increase and milling stages performance period decrease. Another convenient function is the useful area determination, which allows the specialist to choose the areas on the object that require extra attention. A drastic reduction in time is also possible due to multiple times start function. This makes possible to work ion several projects at one time.

HyperDENT Compact

HyperDENT Compact was created as a response to challenges of fast growing dental market in terms of milling process. Herewith this version comprises all the key features that hyperDENT is famous for, including speed, safety, accuracy and many others.

With its impressed new, fully user-friendly interface, long-term employee training is not required for those who have no experience of working with CAM systems. The managed workflow provides true added value for high-end newcomers.

Why HyperDENT

Thanks to the high level of automation, the system is ideal as a “one-button solution” not only for small-sized labs but also for highly specialized milling centers.

Users having little CAM experience work reliably with the standard version thanks to fully automated processes and input data used.

Professionals on the contrary can easily adapt PRO version for their needs.

hyperDENT is also already being used in the dental industry to manufacture implants and prefabricated abutments.

The digital production process using hyperDENT is fully automated and customized thanks to user-friendly interface and the unified CAM software package.

One of the most significant advantage of the system is complete freedom in creating full-fledged strategies while implementing projects using all-in-one milling technology. Other advantages include:

Advantages of hyperDENT

– Possibility of using almost all types of materials available

– Flexible add-ons and adjustable performance features

– Continuous possibility of software upgrading and development

Moreover, hyperDENT is suitable for almost all production environments and offers excellent opportunity to open up new areas of the dental market.

With hyperDENT, a wide range of dentures can be reliably and economically milled.

Stored processing templates reduce the programming effort and ensure the highest possible process reliability.

This spectrum is extended to meet requirements.

HyperDENT thus offers you a future-oriented basis with which you can also open up new markets.

The PRO version of hyperDENT also gives experienced users the option of adapting machining templates individually or creating new ones.

With hyperDENT you are well prepared for the requirements of today and tomorrow.

User interface

Mostly models of the dentures to be manufactured are scanned and processed with a CAD system.

hyperDENT can process STL data records from any upstream scan and CAD process.

You can also optimize the processes with hyperDENT.

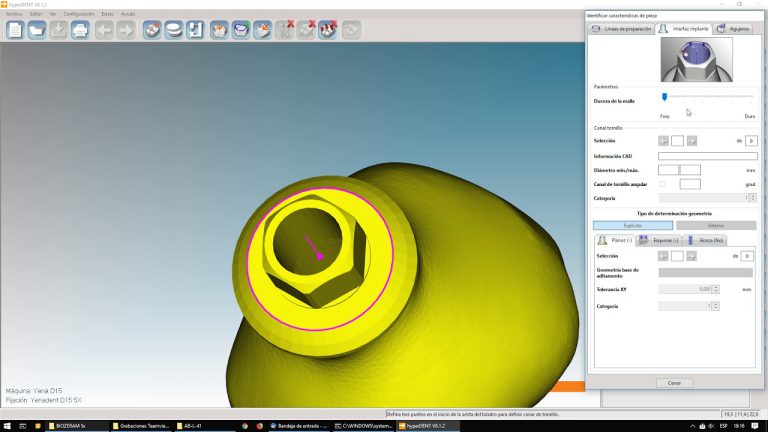

As this CAM solution also offers direct interfaces to various CAD systems such as the DentalDesigner TM (3Shape) exocad or Dental Wings. Objects can be imported from CAD systems with additional information such as insertion direction, preparation limit, screw channel or emergence profile via direct interfaces.

Many conventional systems for the digital production of dentures only allow the use of certain materials and / or material from one provider.

hyperDENT makes your choice flexible. You are not limited either in the choice of the supplier, in the material itself or in the shape of the blank, such as a blank or cylinder.

This flexibility means:

You always acquire the materials that you currently want to use.

And you can purchase from the supplier who offers the desired material at the best price in the required quality.

High process reliability

HyperDENT offers special mechanisms to improve the quality of parts, especially when processing materials that are difficult to machine, such as cobalt chrome or titanium.

The automatic raw part tracking ensures process reliability for rough milling and residual material processing.

The tool can be protected by rounding the toolpaths in corners.

This optional function can be selected in the machining template for hard materials.

The cap-specific machining alignment also ensures precise milling results with cobalt-chromium alloys or titanium.

Expandable at any time

The material, geometry and color of the raw parts are managed in a database.

They can be supplemented with new materials and formats at any time.

As a result, the system can be expanded very quickly with new raw materials sold onto the market.

This flexibility ensures that you can quickly and flexibly adapt to new market requirements.

Reusable:

A raw part is not always fully utilized.

That is why hyperDENT can reuse the partially machined raw parts.

The raw part control function enables quick and easy selection of these raw parts.

Thanks to the “Preview” function, used raw parts are clearly displayed.

This enables them to be identified and reused quickly and safely.

hyperDENT is a CAM system that is open on all sides.

Dental laboratories can use it to put together a solution that is individually customized to them.

Scanners, CAD / CAM systems and milling machines from different suppliers can be combined with one another according to individual requirements.

Each hyperDENT user can choose the add-on module that will complement or improve existing software.

The system has the grinding module that suits for the production of glass ceramics due to extra added toothpaths; template generator function and abutment creator to respond to new complex challenges in the restoration practice.

HyperDENT is very fast in calculations and milling. Moreover, it provides excellent edge fit and excellent surface quality.

This software is perfect for small dental laboratories, milling centers and for dental clinics with laboratories.

It offers:

– complete guided workflow from the initial stage up to the very end of the project;

– optimized and adapted prefab machining for closed fixtures;

– engraving;

– template editor function;

– visual feedback (which is very important to assess the efficiency and the result of the entire project);

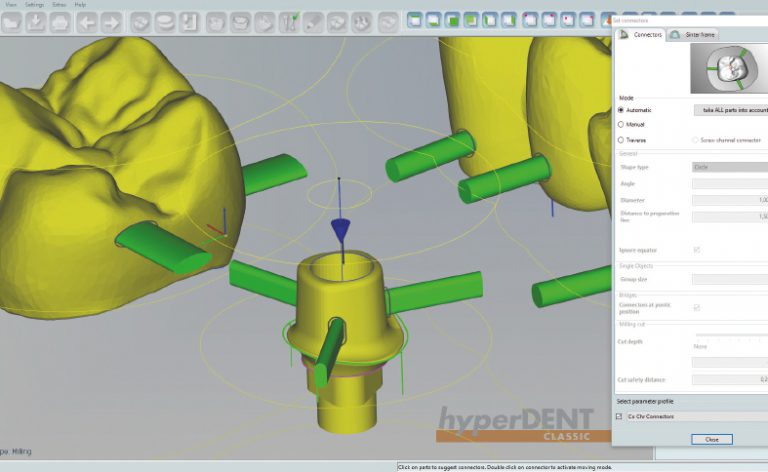

– advanced connectors;

– C-clamp machining;

– easily and fast defined multilayer blanks.

A distinctive feature of hyperDENT is its quality technical maintenance and service. Everywhere in the world, every customer may be provided with advanced maintenance and training.

hyperDENT PRO version is the high-end solution for experienced CAM users. While hyperDENT Classic can be run multiple times to work on multiple projects at the same time. This will ensure the optimization and efficient use of CAM system.

PRO version offers the following powerful functions:

– Configurable materials for the blank types

– Configurable tools

– Configurable tool holder

– Special function for the development of inlay / onlay bridges

Machining templates with freely configurable milling strategies to adapt to the requirements of the existing object type

– Supplied machining templates with standard parameterization for zirconium oxide, cobalt-chrome, PMMA and titanium

Each step can be adapted to individual requirements, settings can be configured and processing instructions for special tasks can be easily defined.

HyperDENT thus also offers highly qualified milling centers with multiple milling units a flexible solution that allows it to take on new challenges and optimize processes efficiently and accurately.

Follow your intuition and instincts in creating high quality projects in few steps with visual feedback and clear understanding of the final result.

Get fully adjustable and customized restoration project at all stages of its development and realization in few guided steps with new functional features of our high-end system.